Pacific Motorway (M1) Watland Street to Sports Drive Upgrade

Project Overview

As principal contractor for the Pacific Motorway (M1) Watland Street to Sports Drive Upgrade, JF Hull in Joint Venture with Bielby Holdings (BHJV) delivered 3.5 km of upgraded motorway and 3 km of new busway infrastructure, enhancing transport connectivity and capacity. Works included six new bridges, major crossings at Springwood and Logan Roads, a 950 m elevated veloway over Logan Road, and a new M1 on-ramp at Lexington and Springwood Roads. Two underpasses support the extended Southeast Busway and veloway. JF Hull completed the full scope, including earthworks, bridgeworks, station construction, and landscaping, while managing interfaces with adjacent contractors, road users, residents, shopping centres, and schools.

The team also delivered the Rochedale Park ‘n’ Ride and Bus Station under a sole-source variation, awarded for strong project performance. The facility includes parking for 485 vehicles, kiss ‘n’ ride bays, a pedestrian bridge, entry plaza, signalised intersection, active transport links, solar panels, and 24/7 CCTV.

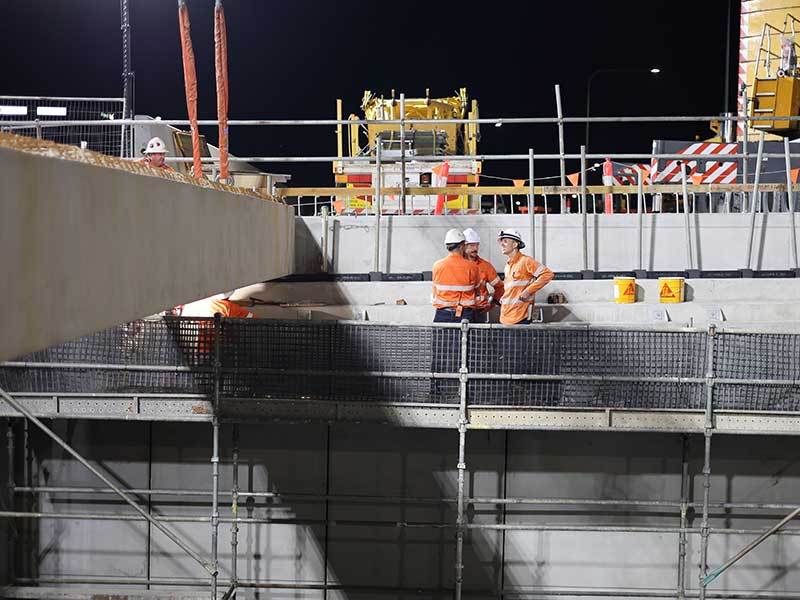

Delivered on a constrained brownfield site along Queensland’s second busiest motorway (155,000+ vpd), the project required meticulous planning and traffic management. Challenges including severe weather, COVID-19, labour shortages, and supply disruptions were managed through continuous day and night works over 4.5 years.

The project’s success demonstrates the team’s ability to deliver a complex motorway upgrade through effective interface management, collaboration, and risk mitigation, achieving outstanding outcomes for Transport and Main Roads (TMR).

Project Director: Clayton Smith

Construction Manager: Sam Carr

SPE: Matt Lacey

Commercial Manager: Danielle Heyes

Superintendent: Andrew Simonson

Quality Manager: Barry Story

Environmental Advisor: Alyssa Stark

Scope of Works:

In joint venture, JF Hull were responsible for all environmental and sustainability management, community and stakeholder engagement and training and development initiatives throughout project delivery. Key areas of relevance to the project included a priority focus on safety for the workforce and surrounding stakeholders (including travelling public / local residents / existing operations) and commitments to maintain the highest levels of environmental and sustainability performance. The project scope data included:

- 127,546t asphalt placed

- 67,745 m3 concrete used

- 4,227t reinforcing steel used

- 275t bus station structural steel erected

- 200,000m3 earthworks and pavement works

- 10,000m drainage culverts and pipes

- 447 Bridge Decks Units

- 16 Super T’s

- 13,992m of new permanent concrete safety barriers

- 7,585m2 of new noise walls

- 60,000m2 of landscaping

- 45,000 native trees/ shrubs / plants

- 25 existing public service utility relocations

350+ new LED streetlights installed

Key Achievements:

- Successfully completed four major traffic switches on the M1 Motorway.

- Reconstructed the Logan / Compton / Lexington Intersection under live traffic.

- Reconstructed the Rochedale Rd Off Ramp and Rochedale Rd intersection under live traffic.

- Reconstructed Lexington Road over a year of night shifts with zero community complaints.

- Successfully closed Sports Drive On-Ramp while opening the new Lexington Road On-Ramp.

- Supply and installation of a 50m long steel truss section for the middle span of Bridge BR65.

- Optimised staging and design in collaboration with the client, achieving a 40-day reduction in the construction program.

- Delivered an additional $162 million in works alongside the main contract, without extending the overall project timeframe.

- Delivered under budget, demonstrating effective cost control and financial management.

- Received Highly Commended recognition in the QMCA Collaboration Award, highlighting excellence in industry partnership.

- Constructed and progressively opened a 3–3.5 km veloway ahead of schedule, in collaboration with TMR, enhancing cyclist safety and delivering early public access and community benefits.

- Extended the DL5000 culvert with a 350m, three-cell 2400×2400 RCBC, involving deep excavation to 11.5m adjacent to live traffic. Delivered 423 precast units and 3,600 m³ of in-situ concrete during wet-season La Niña conditions.

- The project is currently on track to obtain the certified ISC rating of “Excellent” for construction

- Over 537 water quality tests conducted for water discharging site without any site caused issues.

Project Outcomes and Performance

Social

High-Profile TTM with Complex Interfaces

TTM requirements have been high profile with extreme site constraints and interfaces. Solutions have maintained outstanding travel time certainty, with no additional travel time delays. Using six TTM stages and more than 100 site-specific traffic guidance schemes (TGSs), complex traffic changes have been expertly managed. This includes successfully closing a decades-old on-ramp while opening a new on-ramp, and reconstructing the constrained Logan/Compton/ Lexington Roads intersection under live traffic.

Training and Indigenous Milestones Exceeded – 6 Months Ahead of Completion

To date, 139% of target training hours, 532% of target Indigenous participation hours, and 173% of Indigenous spend targets have been achieved six months ahead of project completion.

Economic

Smart Sequencing Driving Program Savings Through Collaboration

While replacing the M1 bridges over Logan and Springwood Roads, one initiative JF Hull introduced was an innovative solution to construct a new northbound bridge stage and a portion of the new southbound bridge concurrently. This structures solution reduced construction from four to three stages, reducing traffic and program impacts by four months – a valued win for road users and the local community – while creating cost savings and the highest levels of safety for the workforce, road users and community members.

The project inducted 3,564 personnel and achieved 2.165 million labour hours, with 97% of materials sourced locally from Southeast Queensland and the remaining 3% from elsewhere in Australia, with minimal overseas content. Over 51 months, only three traffic control closure overruns were recorded on the motorway. JF Hull worked closely with TMR to open sections of the work early, minimising disruptions to the local community and through traffic.

Health, Safety & Environment

Call Up, Acknowledge and Proceed (CAP) Initiative

After a near miss involving an excavator, light vehicle, and pedestrian, the project introduced the CAP (Call Up, Acknowledge, Proceed) protocol to enhance mobile plant safety. Under CAP, personnel must call the operator before entering the operating zone, wait for acknowledgment, proceed only when safe, and notify the operator once clear. Communicated via Toolbox Talks, inductions, and signage, CAP has significantly reduced plant incidents and improved workforce communication. Developed by plant operators and championed by management, the protocol is now being adopted globally across joint venture projects as a standard safety measure.

Community & Customer

Proactive Engagement and Effective Communication Minimised Community Disruption

Strong stakeholder ties and early engagement helped minimise disruption and maintain support, including:

- Replacing a cast in-situ barrier with a slipform method, cutting the task from six weeks to two days

- Consolidated routine messaging reduced fatigue and improved response to high-risk updates

- Close collaboration with Logan City Council and Translink enabled unified community messaging

- Face-to-face meetings with senior project team members built trust and credibility

- Monthly coordination between BHJV, TMR, and engineers aligned milestones with communication strategies for earlier updates and better impact mitigation.

- Early engagement with businesses on Lexington Road, particularly 1–15, incorporated feedback on after-hours work and vibration monitoring for sensitive equipment

- Staged openings of V1 sections gained support from cyclists and user groups

- Traffic Management Liaison Group meetings with Translink, Clarks, and emergency services enabled road impact discussions and key contacts

- Expanded communication for high-impact activities such as overhead gantry installations, piling, bridge demolition, and stitch pours ensured broad awareness and preparedness

Delivering Certainty, Quality, and Collaborative Results to TMR

- Time Surety: The team consistently met key milestones, including major arterial and M1 closures requiring long lead times and precise execution

- Quality Outcomes: Six months from completion, the team is achieving strong CPR scores, with 93.6% lot closures, 97% NCR closures, and high performance in redline markups and 12DA data

Collaborative Gains: A six-month program saving was achieved through collaborative redesign of permanent and temporary works with TMR, the Administrator, and designers

Innovation

- Construction-led temporary works, developed with designers, TMR, and the Administrator, enabled major staging gains. A steel prop supported a partial cantilever pier headstock over Logan Road, removing a traffic stage and saving six months on the critical path

- For Bridge 10, revised staging enabled partial southbound bridge construction and on-ramp realignment six months early, avoiding risky demolition, removing a motorway stage, and improving efficiency while maintaining safety

- At BR01, the 53m-long, 6.6m-deep underpass was built in a single mobilisation by modifying TTM and installing soil nails early. This eliminated a full traffic switch, sped up off-ramp works by four months, and simplified soil nail wall construction

“This has been an exceptional project in every aspect. I’m not aware of any other project in the state that has run for nearly 5 years, and has finished within the project budget and at least six months ahead of schedule.”

Paul McCormack – Site Administrator (Drive Engineering Pty Ltd)